Description

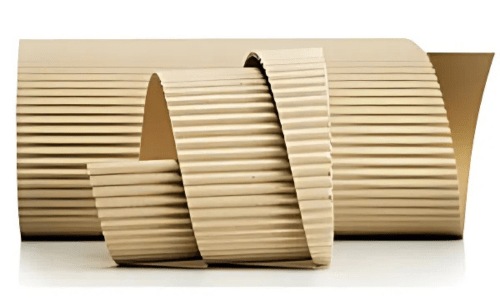

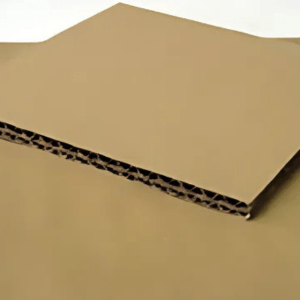

The corrugated layer in corrugated board is used as a wavy layer between two sheets of paper. The basis weight of the corrugated middle layer ranges from 80 to 200 grams per square meter. The corrugated layer provides the required strength to the cardboard. The most important properties of this paper type should be rigidity and resistance to crushing and breaking. Mechanical strength properties such as tensile strength, cracking, and tearing are not considered as significant. In many cases, the appearance of the paper can be overlooked. A special feature of corrugated paper is its ability to pass through the converting machine. This passing ability refers to the sheet’s capacity to withstand stresses and strains during the corrugating process without cracking or breaking. Two factors that enhance sheet passing ability are high stretchability and the absence of wood fines and bound fibers. These characteristics are achieved through good pulp refining and reduced tension during the sheet drying process to optimize stretchability in corrugated paper. Fluting paper must have higher water absorption than test liner paper because very low water absorption can prevent glue from penetrating the paper. Since fluting paper acts as a shock absorber in cardboard sheets and its corrugated structure must be capable of distributing the applied forces to the package, this paper type must maintain its strength and recover after environmental forces are applied.

| method | weight | amount | item |

| ISO200 | 1 gram | 1 | Basis weight |

| ISO400 | 5 grams | 5 | Moisture |

| ISO500 | 51 Grams | 15 | Breaking length (MD) |

Reviews

There are no reviews yet.