Description

Kraft Liner paper is made from 80% to 100% wood pulp (virgin or first-use pulp). If a paper is produced using 100% recycled paper, it is referred to as Liner, and if it is made of two layers, it is called Test Liner. In Iran, when a small percentage of high-quality pulp is added to this type of paper, it is commonly referred to as “semi-Kraft.” It is worth noting that the more the amount of paper pulp is reduced in Kraft paper production, the closer the product’s quality becomes to Test Liner paper.

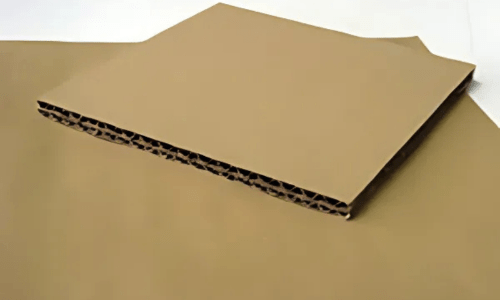

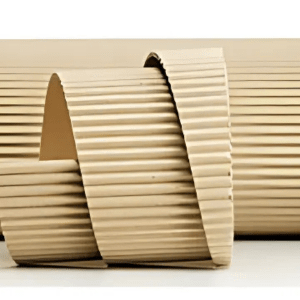

Test Liner paper is used in the production of corrugated sheets, and depending on its quality, it can be used for both the top and bottom layers. The basis weight of this paper ranges from 90 to 220 grams per square meter. The Test Liner paper used for the top layer of cardboard has special technical characteristics, such as the lower water absorption of the top layer compared to the bottom layer. The reduced water absorption of the top layer is due to the protection of the cardboard from environmental moisture and its good printability. The higher water absorption of the bottom layer is due to better adhesion to the fluting paper. Additionally, Test Liner paper has suitable surface resistances for high-quality printability.

Reviews

There are no reviews yet.